Emergency Repair of Underground Cat6 Cables for a Builder

Overview

Our head Internet technician, Jason, was called out to a job in Lilyfield to address a critical issue for a builder client. During construction, the team had accidentally cut through underground Cat6 cables, which were essential for linking multiple buildings on the site. These cables were not just for data transmission but were crucial for the site’s telecommunications, including internet and phone lines. The unexpected disruption had rendered several buildings without connectivity, and immediate repair was needed to restore functionality.

The Challenge

The builder had accidentally severed critical underground Cat6 cables that linked the main telecommunications framework across multiple buildings. The cables were routed from the main distribution frame (MDF) through various conduits, with connections running beneath the garden and into internal frameworks of the affected buildings.

The key challenges included:

- Identifying Severed Cables: Multiple cables were cut, and the configuration was not straightforward due to the lack of uniform wiring standards between connection points.

- Underground Obstructions: The existing conduits had bends and tight spaces that complicated pulling new cables through.

- Misconfigured Wiring: The previous installation had inconsistent pin configurations across connection points, adding another layer of complexity to the repair.

The Solution

Step 1: Identifying and Mapping the Severed Cables

The first step was to identify where the cables were severed and determine which cables linked specific points. Without clear markers or wiring maps, Jason used basic visual alignment techniques to match cables based on their positioning. He marked each cable end to keep track of which connections needed to be re-established.

Step 2: Preparing and Pulling New Cables

Jason planned to pull in brand-new Cat6 cables through the existing conduits. However, due to the bends and narrow passages, he decided to pull two cables at a time from each end to avoid excessive resistance that could cause cables to snag or become stuck. He also taped the new cables to the damaged ones to ensure smooth pulling and prevent losing cable ends within the conduit.

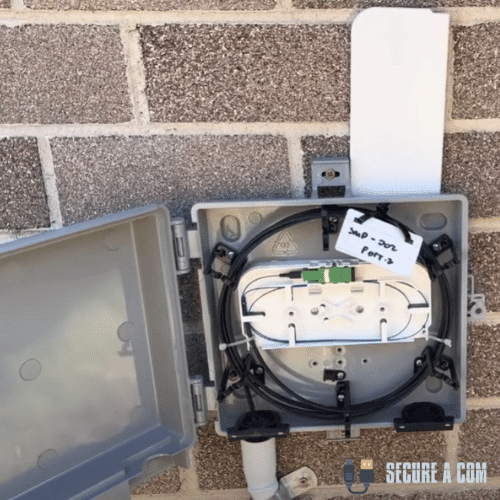

Step 3: Managing Conduit Repairs

During the cable replacement, Jason found that part of the conduit was damaged and too low beneath the surface, making it vulnerable to further damage. He repaired the conduit using a 25mm grey pipe and secured the joints with PVC cement to ensure stability and protection for the new cables.

Step 4: Reconnecting and Terminating Cables

Jason meticulously re-terminated the cables, following the exact, albeit inconsistent, wiring patterns that were used previously. One side was configured in the standard blue-orange-green-brown order, while the other had an unusual pattern. He chose to replicate these inconsistencies to avoid further complications, ensuring that the system would function as it had before the damage.

Step 5: Testing and Validation

After all connections were restored, Jason conducted thorough tests to confirm that all buildings regained their phone and internet connectivity without cross-wiring issues. Despite the challenges, the repaired connections performed as expected, and the site was fully operational once again.

Key Takeaways

- Attention to Detail: This job highlighted the importance of careful mapping and consistent labelling of cables during installation to avoid confusion during repairs.

- Adaptability: Encountering unexpected configurations and physical obstacles required on-the-spot problem-solving and flexibility in approach.

- Use of Correct Materials: Employing Cat6 cables with moisture-resistant properties ensured that the repair would withstand underground conditions, reducing the risk of future connectivity issues.

Conclusion

This case demonstrates the complexities of working with underground telecommunications infrastructure and the need for precise and adaptable approaches in the field. By leveraging expertise and meticulous planning, the SECURE A COM team successfully restored connectivity, maintaining our commitment to high-quality service and rapid problem resolution for our clients.

Jason Kearney

Head Internet Technician

Jason Kearney is the Head Technician at SECURE A COM, with qualifications spanning NBN, ADSL, phone, and data cabling. Starting as an electrician, Jason quickly delved into the telecommunications sector, leading crucial projects like the rehabilitation of the Telstra network. With credentials in both managerial and technical aspects, he now specialises in phone line and NBN fault location and repair, serving both homes and businesses with effective and personalised telecommunications solutions

More Of Our Case Studies

Resolving a Misdiagnosed NBN Connection Issue